May/June 2017

Communities: Construction

Can Construction Crack Code to Higher Productivity?

The potential for improving construction industry productivity is huge, but daunting obstacles stand in the way.

According to a new report, if labor productivity in construction increased as much as it has in retail and manufacturing over the past 20 years, construction’s value added would increase by $1.6 trillion annually—equivalent to Canada’s GDP. Instead, the report says, the construction industry “operates in a way that seems to evolve only very slowly at best.”

In the past 20 years, global labor-productivity growth in construction has averaged only 1% a year. In most advanced economies, there was no growth at all. In contrast, the world economy grew 2.8% and manufacturing grew 3.6%. In the US, construction productivity has remained at the same level as 80 years ago, according to the report from McKinsey and Co., a global management consulting firm.

The productivity deadlock stems from 10 root causes:

- Increasing project and site complexities;

- Extensive regulation, land fragmentation, and the cyclical nature of public investment;

- Informality and potential for corruption to distort the market;

- Opaque and highly fragmented nature of construction;

- Misaligned contractual structures and incentives;

- Custom or suboptimal owner requirements;

- Inadequate design processes and investment;

- Poor project management and execution basics;

- Insufficiently skilled labor at the frontline and supervisory levels; and

- Underinvestment in digitization, innovation, and capital.

What can be done? The report recommends seven areas for action:

- Reshape regulation and increase transparency: Streamline permitting and approvals processes, reduce informality and corruption, and establish more standardized building codes that are outcome based.

- Rewire the contractual framework: Use contracting that focuses on collaboration and problem solving.

- Rethink design and engineering processes: Emphasize techniques such as value engineering, constructability, off-site manufacturing, and precast technology.

- Improve procurement and supply-chain management: Improve planning and increase transparency among contractors and suppliers, create central procurement teams, digitize procurement and workflow, and use predictive replenishment of supplies.

- Improve on-site execution: Follow a rigorous planning process, reshape the relationship and interactions between owners and contractors, ensure that all prework has been completed before starting onsite work, carefully plan and coordinate the different disciplines on-site, and follow lean principles to reduce waste and variability.

- Infuse digital technology, new materials, and advanced automation: Make 3D building information modeling universal; use cloud-based control towers that assemble accurate data in near real time that is both backward looking and predictive; use lightweight materials and advanced automated equipment, introduce the use of predictive analytics, and hire innovation officers.

- Reskill the workforce: Emphasize continuous training through apprenticeship programs, focus on core skills that are underdeveloped, and increase workforce stability by breaking seasonality and cyclicality.

Taking action in these seven areas could increase productivity by 50%–60%, the report says, but the gains could be much greater if construction’s project-based approach was eliminated, where possible, in favor of manufacturing-like mass production.

Signs of progress can be seen and best practices exist, the report adds. “But the question remains whether the various players in the sector, which have different incentives and challenges, will indeed leave behind the status quo and embrace change that will lead to higher productivity.”

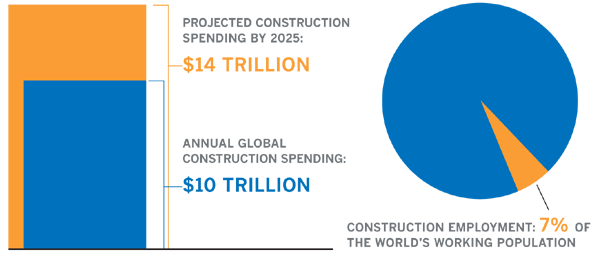

Construction’s Tale of the Tape

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field. The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day:

The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day: