May/June 2019

Communities: Construction

Keep Your Distance

While remote-control technology is certainly not the newest innovation, advances in control systems analysis and radio technology have come so far in the 21st century that engineers and construction workers can now safely and remotely operate heavy machinery like excavators, bulldozers, loaders and cranes—up to hundreds of miles from a work site.

While remote-control technology is certainly not the newest innovation, advances in control systems analysis and radio technology have come so far in the 21st century that engineers and construction workers can now safely and remotely operate heavy machinery like excavators, bulldozers, loaders and cranes—up to hundreds of miles from a work site.

John Martens, P.E., a principal engineer for the multidisciplinary engineering and scientific consulting firm Exponent, explains that operators of heavy machinery, like excavators and dozers, can have a difficult time controlling a machine from inside the cab, especially while on unstable ground. Even the most experienced operators, he adds, can struggle with clunky controls, low visibility, or other challenges, which could not only jeopardize progress on a project, but also put worker safety at risk.

“I think the main benefit of remote-control systems, while they may still have their various flaws, is that they can allow operators to work without endangering themselves or others,” says Martens, who has more than 25 years of experience researching, designing, constructing, and analyzing control systems. “It also allows operators a full view of their surroundings and the work area that might otherwise be limited from inside the cab.”

Automation advances have allowed for increased safety in remote-controlled equipment. Firms like Caterpillar and John Deere have developed proximity sensors that work like rear-view and side-view sensors on automobiles, while using alarms or notifications to warn machine operators and other workers of each other’s presence.

In 2017, Caterpillar—among other companies—showed off its remote-control system technology at Con-Expo, the largest construction trade show in North America. The company allowed attendees to control a fully-operational loader at a worksite 1,400 miles away in Illinois using a radio-frequency remote control and a live-feed from cameras mounted all over the loader.

Stanley Infrastructure developed a controller similar to Microsoft’s Xbox gaming console featuring joysticks, a directional pad, and emergency stop buttons that works using radio frequency after operators plug in and install the system in their vehicles—meaning the operator can switch between manual and remote control at the press of a button.

The new technologies could be a step toward attracting young, tech-savvy engineers into construction, according to Martens. “When you have the technology available where you can almost guarantee no compromises to worker safety and can incorporate cutting-edge ‘techy’ elements, I definitely think you will see more young people looking at careers in construction,” he says. “That, however, does come with new issues and risks you have to consider.”

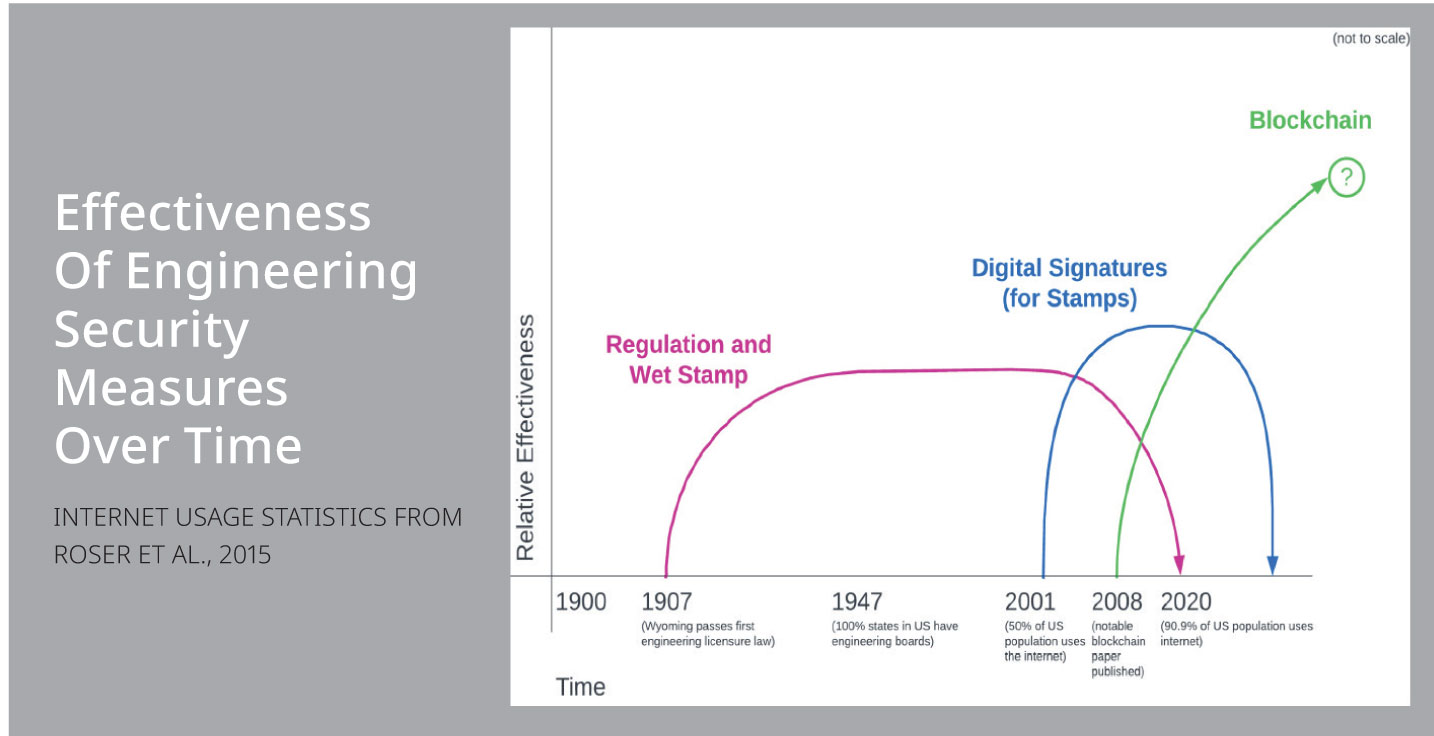

Those risks include standardizing and ensuring the competency and training of remote-control operators, potential time lag that limits an operator’s ability to control machines with the highest level of precision, and potential security risks allowing the potential of attacks from hackers or disruptors within range of the radio traffic.

In January, security software company Trend Micro Solutions published a study showing the ways that radio-frequency technology could be intercepted and abused. Anyone within range of the construction site could obtain basic control of a machine by recording the operator’s commands, capturing the data, and retransmitting the recorded commands.

To combat this, the study suggests that companies take countermeasures like software protection and properly securing computers with rolling code transmitters to prevent replay attacks.

While the risks associated with remote-controlled equipment will require further innovation and standardization in the construction industry, engineers like Martens believe the benefits of worker safety and increased work efficiency outweigh the negatives.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field. The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day:

The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day: