May/June 2018

Variables

Remaking the Hockey Rink

A “RETHINK THE RINK” MAKE-A-THON ALLOWED CARNEGIE MELLON UNIVERSITY ENGINEERING AND SCIENCE STUDENTS THE OPPORTUNITY TO DEVELOP PROTOTYPES FOR REDESIGNING HOCKEY RINK BOARDS TO REDUCE THE CHANCES OF INJURIES TO PLAYERS. THE PROGRAM IS A PARTNERSHIP WITH THE PITTSBURGH PENGUINS NHL TEAM, CARNEGIE MELLON UNIVERSITY’S COLLEGE OF ENGINEERING, AND HIGH-TECH MATERIALS COMPANY COVESTRO.

A “RETHINK THE RINK” MAKE-A-THON ALLOWED CARNEGIE MELLON UNIVERSITY ENGINEERING AND SCIENCE STUDENTS THE OPPORTUNITY TO DEVELOP PROTOTYPES FOR REDESIGNING HOCKEY RINK BOARDS TO REDUCE THE CHANCES OF INJURIES TO PLAYERS. THE PROGRAM IS A PARTNERSHIP WITH THE PITTSBURGH PENGUINS NHL TEAM, CARNEGIE MELLON UNIVERSITY’S COLLEGE OF ENGINEERING, AND HIGH-TECH MATERIALS COMPANY COVESTRO.If you’re a die-hard hockey fan, the last thing you want to hear is that your team’s best player is injured and out for a game…or even worse, the season. The injuries sustained by professional and amateur hockey players aren’t just painful, they’re also costly.

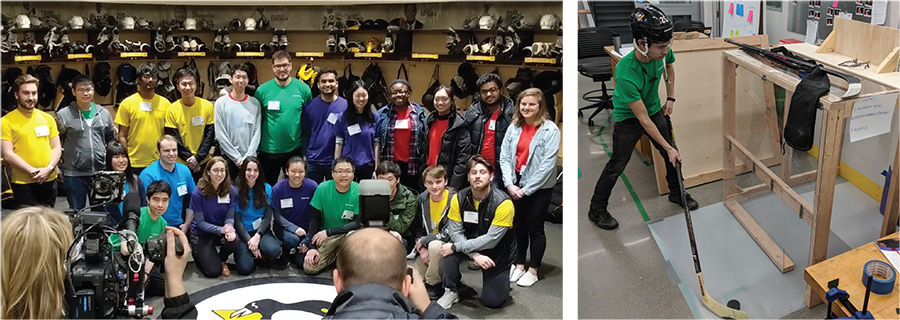

To address this issue, the Pittsburgh Penguins NHL team, Carnegie Mellon University’s College of Engineering, and high-tech materials company Covestro recently partnered to improve player safety. In March, a “Rethink the Rink” week-long make-a-thon allowed 25 engineering and science students the opportunity to brainstorm ideas and develop prototypes for redesigning the hockey rink to reduce the chances of serious injuries.

In hockey, the play of the puck bouncing off hard boundaries has been given a priority over cushioning the players, says Diana Haidar, an assistant professor of mechanical engineering and makerspace director. The challenge for the students: How do you keep the excitement of the game, but make it safer for players?

More than 50% of National Hockey League players miss at least one game during a season due to injuries, according to a 2014 study by Michael Cusimano, a neurosurgeon and researcher at the University of Toronto. The study was commissioned to show the economic impact of injuries in hopes of increasing interventions and improving player safety. A review of player injuries during two seasons revealed a total salary cost of $218 million per year.

Students were selected for the make-a-thon based on their answers to questions such as why this problem mattered to them. “Coaches, team owners, and hockey fans don’t like it when their team’s players are out with injuries for the season,” says Haidar. “The students that applied were all optimistic about helping to solve this real-life issue.”

Participants were tasked with redesigning the rink boards so that players will sustain no or less serious injuries when hitting the boards. At the same time, participants needed to ensure that the puck will bounce off the boards in the same way it does on currently used boards.

The make-a-thon offered Carnegie Mellon a chance to provide an additional hands-on learning project for students. The university is focused on developing a “maker ecosystem” to enhance the curriculum in undergraduate and graduate programs. The College of Engineering recently opened the Tech Spark makerspace, a facility with labs where students can use design space, rapid prototyping machinery, laser cutters, 3D printers, and traditional milling machines.

On the first day of the make-a-thon, the Penguins’ facilities manager and equipment manager, a former player, and a team doctor provided details about the history of hockey rinks and the types of injuries that players are likely to sustain. The students were also briefed by Covestro staff, who also served as expert coaches, about the properties and functionalities of different types of materials to redesign the board.

Five teams had to come up with several ideas and were given two days to assemble their prototypes with feedback from faculty members and Covestro expert coaches. The week ended with a “pitch day” at the UPMC Lemieux Sports Complex in Cranberry, Pennsylvania, where the teams presented their prototypes to a panel of judges, which included Jerry MacCleary, CEO of Covestro, and David Morehouse, CEO of the Pittsburgh Penguins. The prototypes will be submitted to the National Hockey League and USA Hockey for further review and potential testing by amateur players.

The participants, says Haidar, enjoyed the experience because it gave them a representation of real-world engineering with idea generation, theoretical calculations to support their ideas, and prototyping. “They learned to collaborate with people with different backgrounds working toward the same shared goal. And they learned that you can’t be successful on a team without some give and take.”

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field. The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day:

The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day: