May 2014

IN FOCUS: EMERGING TECHNOLOGIES

3D Printing: The Next Iteration

Additive manufacturing, in an increasing number of ways, is adding tangible benefits to engineering design.

BY EVA KAPLAN-LEISERSON

Some are calling it another Industrial Revolution. Three-dimensional printing, also called additive manufacturing, has existed for decades. But recently the method has been coming into its own, demonstrating an ability to affect a bigger proportion of modern life.

Last year, the technology gained international attention when the nonprofit organization Defense Distributed posted to its website CAD files for a 3D-printed pistol. The State Department intervened, but the files had already been downloaded at least 100,000 times, according to reports, and then distributed further on file sharing websites.

The gun was a crude first step, and legislative measures have already been taken to address the potential of 3D-printed guns (for instance, requiring the addition of material that can be picked up by metal detectors). But the incident demonstrates two major trends experts say are occurring with the technology: access by more than just a limited number of technical users and applications beyond traditional prototyping.

Increasing Users

The 3D printing process builds objects layer by layer with various materials. This contrasts with conventional subtractive manufacturing techniques that remove material to form objects.

The technology was developed in the 1980s and primarily focused on forming prototypes. This is still a major benefit for a growing number of engineers, who can use 3D printers to help speed the design cycle.

In 2011, Mike Moussa, P.E., founded PartSnap to fill a niche for 3D printing and product development services in northern Texas. He explains that the method enables the ability to quickly iterate. “You can rapidly design something and get it into your hands relatively inexpensively and test it and play with it and tweak the design, print a new part, and iterate again,” he says. That enables engineers to finalize a design before investing tens of thousands of dollars in an injection mold tool, Moussa adds.

It may soon become the norm for engineers to have access to the technology, says Adam Cohen, principal consultant and CEO at Additive Insight, which specializes in 3D printing and additive manufacturing. (Cohen started in the industry in its infancy and has earned nearly 70 patents in the area.) “It will be absolutely the norm for everyone designing something that can be made with these processes, even if it’s just a prototype,” he says. “It will be weird not to. It will become as normal as holding a mouse and designing something on screen.”

But engineers aren’t the only ones gaining access to 3D printing technologies. As prices drop, printers are increasingly reaching the general consumer market. Amazon.com even sells them—the cheapest option, a kit for building your own printer, costs just $336.

Adding Sophistication

As 3D printing has proliferated down to the person on the street, higher-end uses are simultaneously developing. For example, a wide variety of materials beyond polymers can now be used. Metals and wood, biomaterials, even food can be 3D printed.

Cohen believes such developments are accelerating. “I think we’ve just seen the beginnings of what should be possible with these technologies,” he says. “We are on the cusp of something transformative and revolutionary.”

A major change coinciding with the variety in materials is the ability of 3D printing to create end-use objects. In 2012 when PE covered the technology (see “Back to the Future,” January/February), this application was just starting to take off in industries such as aerospace and automotive. Now, in a growing number of industries, 3D printing is creating objects that will serve as more than just prototypes.

Consultants for McKinsey & Co., writing in a January 2014 article, stress that 3D printing has reached a tipping point. With printers’ current ability to handle materials from titanium to human cartilage and create fully functional components such as batteries and transistors, they write, the technology “appears ready to emerge from its niche status and become a viable alternative to conventional manufacturing processes in an increasing number of applications.”

Expanding Applications

New uses for 3D printing are showing the versatility of the technology and have implications for a variety of industries and engineering disciplines. Here is just a sampling.

Building and construction. In the future, large scale structures could be 3D printed, says Adam Cohen. People are now working with concrete printers and powder-based approaches to develop this use, he says, and in a number of years we may see structures such as freeway overpasses built using the method.

An MIT professor of civil and environmental engineering, John Ochsendorf, has been creating models of historic structures such as the Bourges Cathedral in France using 3D scanning and printing techniques, in order to derive lessons about the buildings’ stability and safety. What he and his team learn will not only help to preserve ancient buildings and ensure visitors’ safety but also provide information to help design more efficient modern structures.

Medical. 3D printers can provide critical benefits for patients. At the University of Michigan, doctors and engineers recently collaborated to print a biodegradable splint for a young child who suffered from a rare disorder that caused his bronchi to collapse. According to an article on the university’s website, university biomedical and mechanical engineering professor Scott Hollister created a 3D model of the child’s airway, designed a custom device using high-resolution imaging and CAD, and then used laser-based 3D printing to produce the device, which news reports say saved the toddler’s life.

3D printing is also enabling part production for medical devices, such as custom-fit hearing aids and Invisalign dental braces. According to Chris Williams, director of the Design, Research, and Education for Additive Manufacturing Systems (DREAMS) lab at Virginia Tech, Align Technology is 3D printing molds to make the braces by thermoforming an FDA-approved polymer over a 3D printed pattern.

Robotics and other dynamic areas. Cohen is also a mechanical engineering professor at Southern Methodist University and directs the school’s Laboratory for Additive Manufacturing, Robotics, and Automation. There, researchers are working on the ability to print soft robots, which one day may include printed elements such as actuators and sensors. The work has implications for search and rescue and prosthetics.

3D printing “starts to shine” with complex shapes and multiple materials, says Cohen, areas where conventional manufacturing has difficulty. In addition, the method enables the creation of objects that can change shape, move, react, and sense.

Williams’ DREAMS lab is working on embedding different types of materials in 3D printed objects—for instance a shape memory alloy to allow the object to move and flex and nano particles that change color when exposed to different light.

Defense and aerospace. The military is getting into 3D printing, with potential savings in both time and cost. A blog post from National Defense magazine quotes the commander of the Army Materiel Command in calling the method one of the service’s most promising technologies. The Army may embed printers with troops in order to enable the on-demand creation of components for tools, vehicles, and weapons, according to the article. Two printers in Afghanistan are already producing small parts.

The Army is also looking at 4D printing, adding a transformation dimension that would change an object’s properties when exposed to factors such as water or extreme temperatures. This could have applications for expandable, lightweight body armor, the Army’s chief technology officer told National Defense.

Last year, PE reported on NASA’s project with Made in Space Inc., a California company, to test 3D printing on the International Space Station. That could perhaps one day enable the manufacturing of an entire spacecraft outside of Earth, noted the article. (See “Additive Manufacturing: A Space Odyssey,” July 2013.)

Food. Additive manufacturing techniques are even reaching out to food. The Hershey Co. and 3D Systems are developing a printer for confectionary items. And one PE’s company, Systems and Materials Research Corp., earned a NASA research grant for its technology to print food that can last on long space missions, such as to Mars.

PODCAST: ANJAN CONTRACTOR, P.E., SENIOR ENGINEER AT SYSTEMS AND MATERIALS RESEARCH CORP., TALKS TO PE ABOUT THE 3D FOOD PRINTER SMRC IS DEVELOPING. THE PRINTER MAY NOT ONLY SERVE ASTRONAUTS ON LONG SPACE MISSIONS BUT ALSO HELP FEED A GROWING WORLD POPULATION.

Anjan Contractor, P.E., senior engineer at SMRC and project manager on the effort, explains that the prototype printer takes dehydrated food components and reconstitutes them with water and oils. The early version prints pizza, which works in layers.

The printer will be able to add additional nutrients and vitamins in customized recipes for individuals, says Contractor. It also offers food production benefits as the world’s population increases.

Creating a New Workforce

The transformative effects of 3D printing will require workforce development and training. “If it’s the new manufacturing paradigm that everyone expects it to be, then we have to engage the next generation of engineer,” says Williams, who holds dual appointments in Virginia Tech’s departments of mechanical engineering and engineering education.

Education must include when 3D printing is appropriate to use, what is the best machine and material for a particular job, and then, most important, how to design for it, says Williams, who is co-organizing a National Science Foundation-sponsored workshop on additive manufacturing education.

The professor notes that the ability for engineers to selectively place material where they need it completely changes thinking about product design. Users must be able to take advantage of what additive manufacturing does best, including the integration of design and manufacturing, he says. However, there are no design-for-manufacturing rules yet for these techniques.

Virginia Tech is working hard to involve students in the new paradigm. Design courses enable students to print models and prototypes, and a dedicated class for additive manufacturing is offered as an elective for seniors and graduate students.

A competition sponsored by the Air Force Office of Scientific Research is also challenging students to design small remote controlled vehicles that can be completely 3D printed. Williams points out that this has benefits not only for the military but also in natural disasters.

In addition, the mechanical engineering department offers a vending-machine-style 3D printer, the DreamVendor, that students in any department can use to print school or personal projects. It’s engaging students informally. “We don’t have to tell them, ‘You’re learning,’ because then they might stop,” Williams says. “They’re out in the hallway conversing, planning, learning, teaching each other.”

Tech students also conduct outreach with kids to get them excited not only about 3D printing but also engineering in general. And it reminds the older students “we do some really cool stuff,” says the professor.

Moving Forward

As far as it’s come, the field of 3D printing is still developing. Cost and speed are still challenges, Cohen says. Accuracy could be better (material can shrink a little bit), as could strength (because of the layering process, objects are more likely to break along the Z access).

In addition, so far only one process exists for mass production of (small) objects, he says, which he invented.

Ease of use could also be improved. “You have to consider eight to 10 different things to optimize,” says the Additive Insight CEO. “I expect we will see software that will help with that and largely automates it.” Williams also discusses the need for better design tools. Currently, 3D printing can make things that are more complex than what can be modeled in CAD software, he says. “Making a part [is] hard if you can’t design it.”

And Moussa speaks to the knowledge gap that exists, such as engineers who aren’t well versed in all the different 3D printing processes. A service bureau like his can help point people in the right direction, he says.

Overall, these experts agree that this is an area that engineers need to learn more about. Although 3D printing is not a panacea, Williams stresses, when used appropriately, it offers “so much potential and power.”

“Get educated on what’s going on,” says Cohen. Start to use the technologies now so you can get a sense of what they can do.

As the Additive Insight website proclaims, “If you don’t think 3D printing will impact your business, you probably haven’t given it enough thought.”

Check out the bonus multimedia features:

YouTube Videos

SMRC’s 3D food printer prototype makes a small pizza.

Credit: Anjan Contractor, P.E.

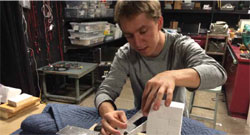

A Virginia Tech engineering grad student shows off the school’s DreamVendor, a 3D printing “vending machine.”

Credit: Virginia Tech

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field. The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day:

The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day: VIRGINIA TECH PROFESSOR CHRIS WILLIAMS (RIGHT) WORKS WITH A STUDENT IN THE SCHOOL’S 3D DREAMS LAB.

VIRGINIA TECH PROFESSOR CHRIS WILLIAMS (RIGHT) WORKS WITH A STUDENT IN THE SCHOOL’S 3D DREAMS LAB. MIT STUDENTS ASSEMBLE A FLYING BUTTRESS USING 3D-PRINTED COMPONENTS.

MIT STUDENTS ASSEMBLE A FLYING BUTTRESS USING 3D-PRINTED COMPONENTS. AN MIT STUDENT PREPARES A MODEL OF 3D-PRINTED COMPONENTS FOR A DISPLACEMENT EXPERIMENT USING LINEAR ACTUATORS AND HIGH-SPEED CAMERAS TO CAPTURE COLLAPSE MECHANISMS.

AN MIT STUDENT PREPARES A MODEL OF 3D-PRINTED COMPONENTS FOR A DISPLACEMENT EXPERIMENT USING LINEAR ACTUATORS AND HIGH-SPEED CAMERAS TO CAPTURE COLLAPSE MECHANISMS. (TOP) SYSTEMS AND MATERIALS RESEARCH CORP. HAS DEVELOPED A PROTOTYPE 3D PRINTER FOR FOOD. (BOTTOM) PIZZA’S LAYERS ARE WELL SUITED FOR 3D PRINTING.

(TOP) SYSTEMS AND MATERIALS RESEARCH CORP. HAS DEVELOPED A PROTOTYPE 3D PRINTER FOR FOOD. (BOTTOM) PIZZA’S LAYERS ARE WELL SUITED FOR 3D PRINTING.