July/August 2019

Communities: Industry

Human Touch Needed in Adopting Smart Technology, Report Shows

Although it sounds counterintuitive, the growing use of automation may drive the need for more human talent in manufacturing and related fields.

A recent report from the Manufacturing Institute and PricewaterhouseCoopers examines how expanded use of technologies such as robotics, artificial intelligence, and automated processes are impacting the manufacturing industry.

As the report explains, smarter technologies are creating the need for irreplaceable human skills such as creativity, critical thinking, and innovation, and talent in areas such as finance and engineering.

Seventy percent of manufacturers surveyed said the biggest impact of robotics on the workforce over the next five years will be an increased need for talent to manage automated work environments, and 73% are planning to increase their investment in smart factory technology over the next year. More than two-thirds of respondents said they were planning to increase their investment in smart factory technology by at least 10%.

According to the report, Navigating the Fourth Industrial Revolution to the Bottom Line, most manufacturers are still in the early stages of moving toward “4IR” (fourth industrial revolution). Of 96 respondents, 37 (39%) said their organization was in either the “awareness” or “immobile” stages of adoption, meaning they are aware of the technologies but have not moved toward adoption or they have a desire to adopt but lack the operational capabilities to do so. Another 29% of respondents are either in the “experimentation” stage, or the “early adoption” stage, meaning they are still determining how to best use the technology or have only just carried out successful proof-of-concept use cases and are considering adding more for greater value.

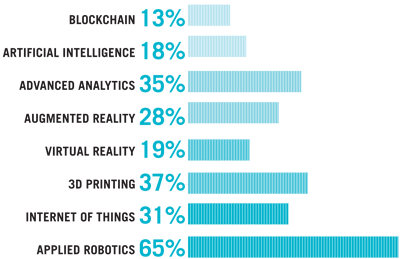

The top four applications manufacturers have deployed in their operations within the last three years are applied robotics (65%), 3D printing (37%), advanced analytics (35%), and Internet of Things (31%).

Manufacturers report plans to upskill and reskill current employees to ensure capable and efficient management of new technologies. Twenty-two percent of manufacturers are providing outside training through community college classes, online training, or outside technology vendors. Another 31% have trained existing employees on how to adopt advanced manufacturing technologies.

As the report notes, manufacturing employers will need to continue to expand their workforce by recruiting engineering, science, mathematics, and technology students in high schools and colleges. They will also need to promote STEM and technology programs and courses at all education levels.

According to Chad Moutray, director of the Manufacturing Institute’s Center for Manufacturing Research, manufacturers could create more than 130 million jobs by 2022 if workers are given significant reskilling and the next generation of workers is trained properly.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field. The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day:

The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day: