January/February 2019

You Said It

The National Transportation Safety Board’s report on the deadly pipeline explosion in Massachusetts in September calls for a significant legislative change that NSPE has strongly advocated for years: elimination of professional engineer licensure exemptions. Here are some thoughts from members.

This unfortunate tragedy in Massachusetts (in addition to wildfires sparked by power lines and countless examples of air, soil, and water pollution caused by industrial sources) shows that the industrial exemption is long overdue for review and elimination. I served for many years on a professional licensing board and continue to advocate for the strengthening of our country’s professional licensing programs. They are essential to protecting the public health, safety, and welfare. The problem—if you will—is that the existing safety net of state-based licensing has worked so well for so long that it has become all but invisible to the public and policy-makers. They no longer appreciate the significant economic benefits of professional licensing. Far too many take for granted that water coming out of the tap is safe to drink, that bridges will be safe to cross, and that buildings are built to protect human life from the worst that nature sends our way.

While I don’t want to take anything away from the rigorous engineering and safety standards enforced by many industrial employers, it’s also fair to say that the licensure exemption for engineering personnel employed by these companies reflects their economic power and legislative influence, not a reasoned assessment of risk and benefit. It’s an administrative convenience and cost-saving measure for industrial employers to have their own engineering staff design, engineer, and oversee construction and maintenance of major elements of our infrastructure free from regulatory oversight.

P. Douglas Folk, J.D.

Scottsdale, AZ

My two recent visits to industrial operations, where both operations had some problems, highlight the issues in the NTSB report. The first operation has pretty significant safety issues that stem from their production processes, which need special precautions to minimize risk. At the second operation, management has recognized the risk of not performing equipment replacement that was deferred for over five years. Both operations have “hidden” conditions and obvious flaws. Both operations want to maximize profit by getting the most from their existing assets. What my industrial visits highlight is the fact that the employed engineer has an obligation to the employer and the public interest is second, whereas the PE has obligations to the public first and then the employer/client. The PE and non-PE has to satisfy both interests. Both firms are seeking independent PEs to fix their issues, but management still has the overall authority to release funding to make corrective action for unsafe conditions.

Francis Stanton Jr., P.E., F.NSPE

Richboro, PA

The talk of the industrial exemption has had me wondering about how the certificate of authority would work for a manufacturer. Typically engineering firms are owned and/or managed by engineers; however, with a manufacturer they are not typically owned or even managed by engineers. My interpretation of the statutes for Missouri is that a responsible engineer is required to obtain a certificate of authority and typically that engineer is an owner or board member. [I]t seems to me from my experience in manufacturing that the trouble in manufacturing is that often the engineer does not have absolute final say about the product leaving the plant. Further, the final decision could lie with someone that does not hold an engineering degree. Maybe a manufacturer wouldn’t need a certificate of authority to operate, but I see that as something that would go hand in hand with requiring licensed engineers in industry. Seems to me that the most valuable part of eliminating the industrial exemption would be putting engineers in position to have a final say, otherwise a licensed engineer can object to something all the way to the point of quitting and the defective product could still make it to the consumer.

We are our worst enemies.

Michael Hernke, P.E.

Little Rock, AR

The real question at hand is whether our licensure model is valid. The USA focuses on the passing of two eight-hour exams, usually with an ABET-accredited degree, although this requirement is not consistent and exam waivers have existed since their inception. If we start to look at the history of accidents in the USA, we should first categorize them as one of three types: technical failure, ethical failure, or breach-of-law failure. I’ve done some research into this and the overwhelming categorization is ethical failure—even if the cause is a technical failure, the root cause is ethical, as the engineer is acting outside of their skill scope. A true technical failure would be one that required a change in the art such as the Tacoma Narrows bridge failure due to harmonic isolation. This raises the question as to why our typical ethics exam is a 20-question trivial pursuit on paragraphs in the rules, when the Canadian system has a four-hour closed-book examination of law and ethics.

We need to eliminate the present PE examination and return to a general FE examination that is an exit requirement for USA graduates of engineering programs and a requirement for EIT/PE registration. The PE examination must be replaced by a law and ethics exam that covers federal and state law while ensuring clear understanding of the ethical constraints on engineering practice.

Derek Gilboe, P.E.

Houston, TX

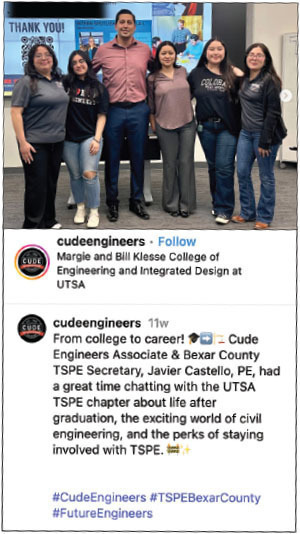

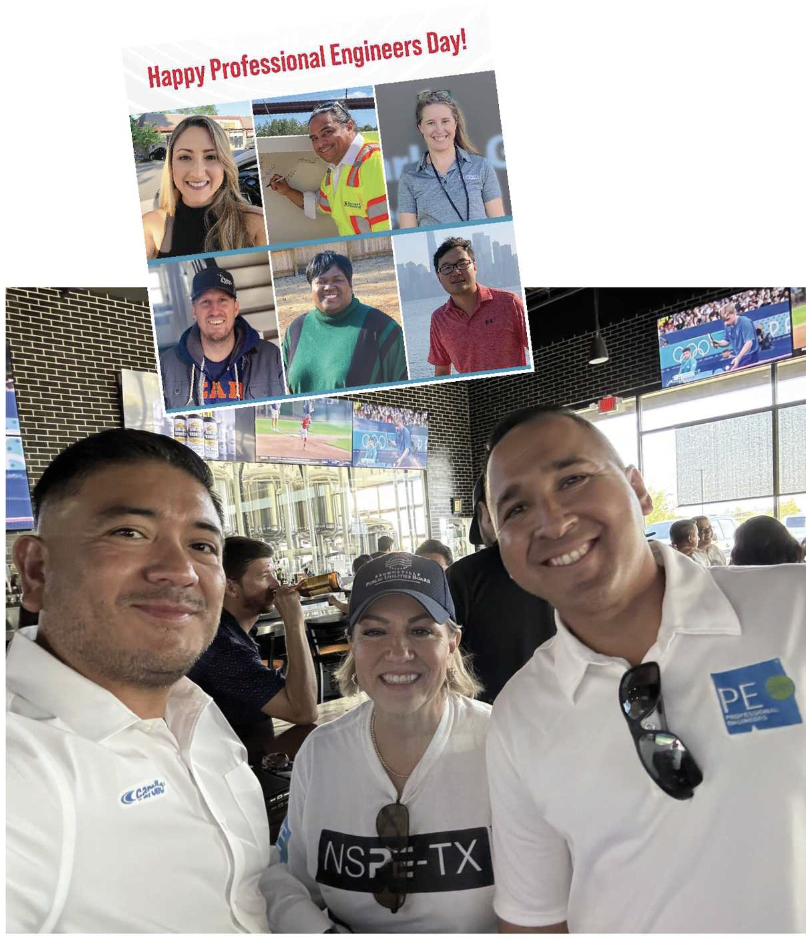

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field.

Volunteering at NSPE is a great opportunity to grow your professional network and connect with other leaders in the field. The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day:

The National Society of Professional Engineers (NSPE) encourages you to explore the resources to cast your vote on election day: